5 Axis CNC Routing...

- heidi8013

- Aug 21, 2025

- 2 min read

Built to match your vision. And outperform it.

What is 5-Axis CNC Routing — and Why Does It Matter?

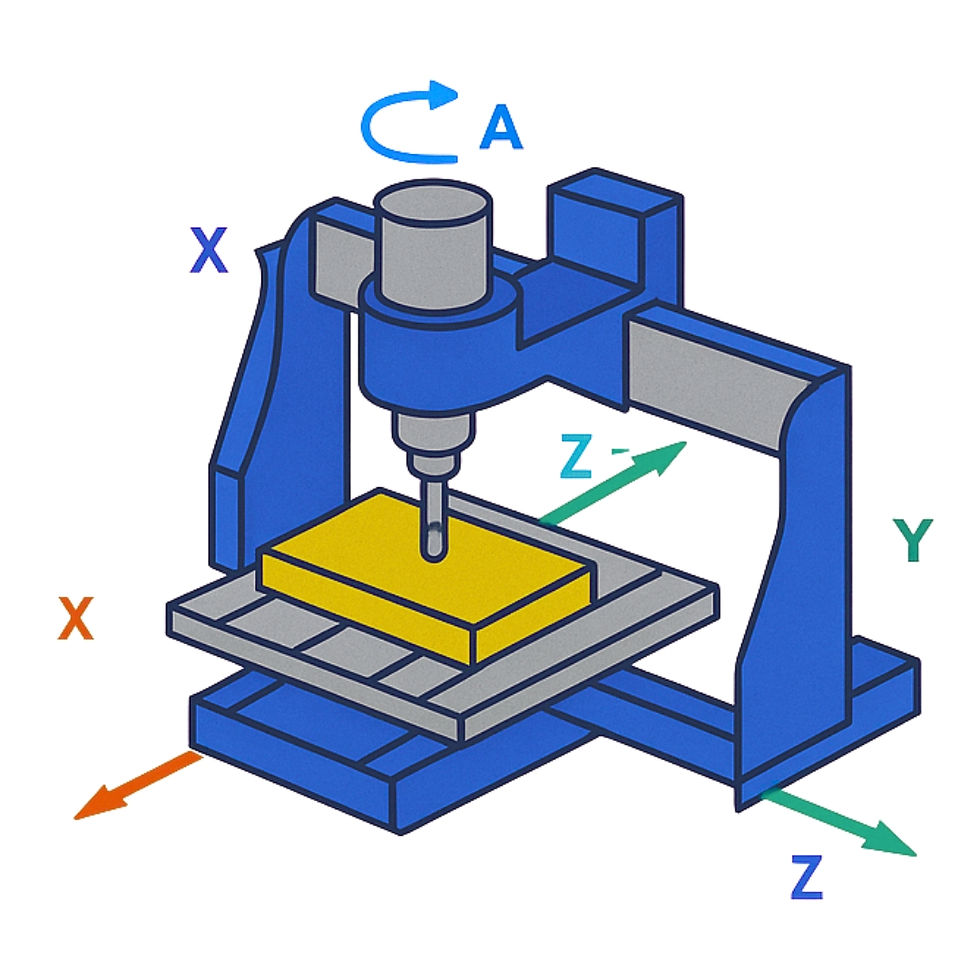

5-Axis Means 5 Directions of Movement

Unlike traditional 3-axis machines (which move along X, Y, and Z), a 5-axis CNC router also rotates on two additional axes — typically A (tilt) and B or C (rotation).

➤ Why it matters: This allows the cutting tool to approach the workpiece from virtually any angle.

More Complex Parts, Fewer Setups

5-axis routing lets you machine multiple sides or complex curves of a part in one setup.

➤ Why it matters: Reduces time, increases accuracy, and eliminates the need for manual repositioning.

Perfect for 3D Shapes and Organic Designs

It can handle sculpted surfaces, undercuts, cavities, and flowing geometries that are impossible on standard routers.

➤ Why it matters: Ideal for aerospace, mold making, custom cabinetry, art, and advanced prototyping.

Smoother Finishes and Cleaner Cuts

Because the tool can maintain optimal cutting angles throughout the process, it reduces chatter and improves surface quality

.➤ Why it matters: Less post-processing, better fit and finish, and less wear on your tools.

Greater Efficiency with Advanced Toolpaths

5-axis machines use synchronized, simultaneous movement that minimizes repositioning and boosts material removal rates.

➤ Why it matters: Get jobs done faster, with more consistency and less waste.

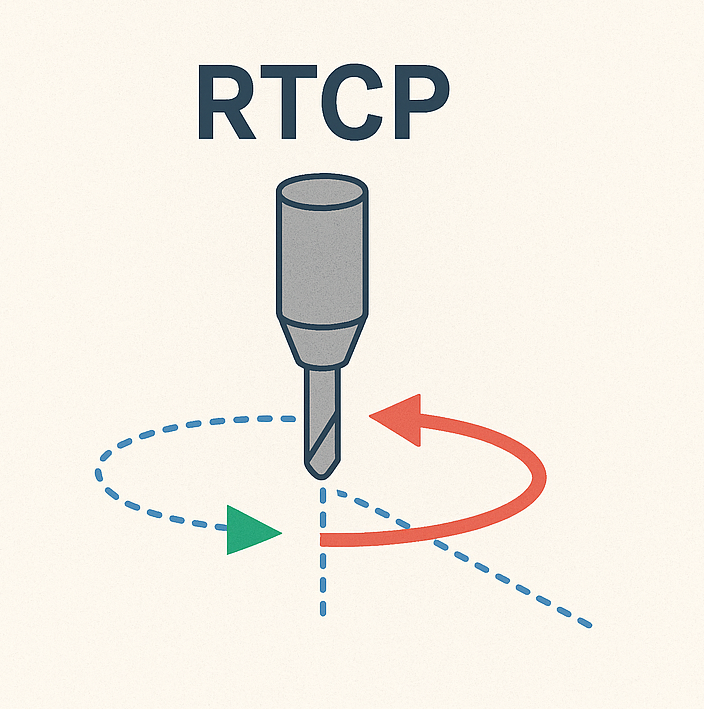

Supports RTCP (Rotational Tool Center Point)

Phantom’s 5-axis system features RTCP technology, ensuring the tool tip remains on the correct cutting path even as the rotary axes move.

➤ Why it matters: Precision control for complex geometries and smoother transitions between tool movements.

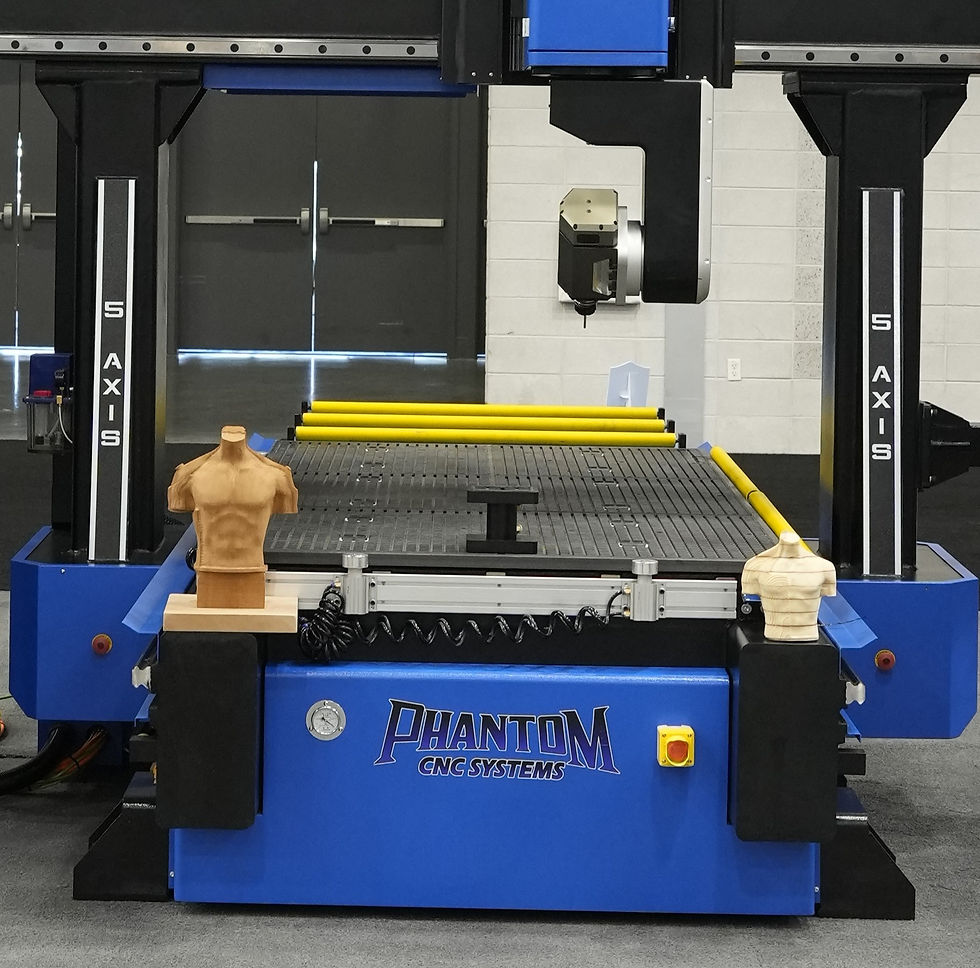

CHECK OUT SOME OF THE LASTEST UPDATES ON PHANTOM 5-AXIS CNC

MORE INFO COMING SOON

READY TO START YOUR 5 AXIS JOURNEY WITH PHANTOM? CLICK BELOW FOR A QUOTE!

Comments